Porcelain Clad Arrester

The arrester is the basis for insulation coordination of various electrical equipment (transformer, reactor, capacitor, engine, motor, PT, CT, circuit breaker, contactor, etc.) in the power system. The internal and external insulation indexes (short-time power frequency, lightning impulse withstand voltage, operation impulse withstand voltage, etc.) of all electrical equipment in the power system are determined by the protection performance of the arrester.

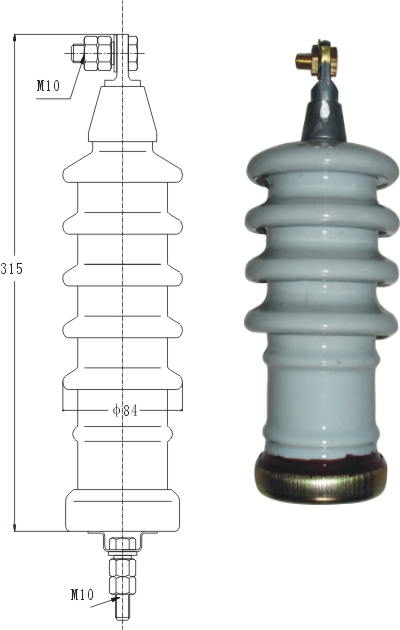

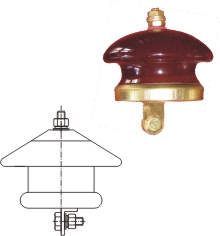

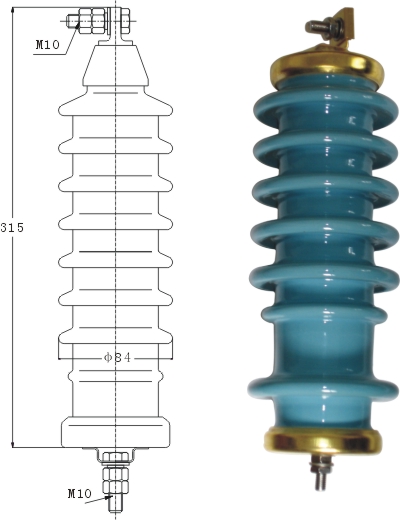

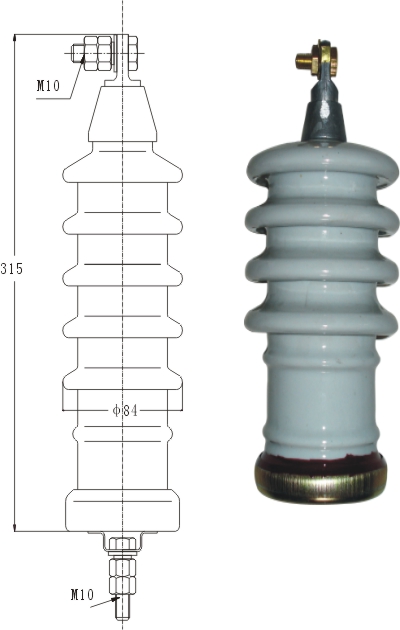

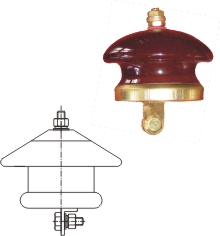

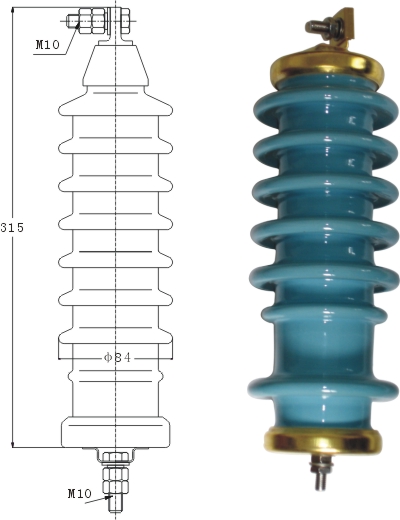

Y. F series porcelain clad arrester

summary

The arrester is the basis for insulation coordination of various electrical equipment (transformer, reactor, capacitor, engine, motor, PT, CT, circuit breaker, contactor, etc.) in the power system. The internal and external insulation indexes (short-time power frequency, lightning impulse withstand voltage, operation impulse withstand voltage, etc.) of all electrical equipment in the power system are determined by the protection performance of the arrester.

The porcelain insulation jacket of the company's porcelain jacket metal oxide arrester is formed by the equal surprise method, with high density and good electrical insulation. Equipped with unique sealing process and pressure relief device, it is safe and reliable, and widely used in various power places. Porcelain coated arrester has a long service life and good texture. It is an ideal product integrating durability and beauty.

Porcelain sheathed metal oxide surge arresters are the most advanced products of conventional surge arresters in the world. They have excellent nonlinear volt ampere characteristics, fast steep wave response and large flow capacity. After China fully introduced zinc oxide technology in the mid-1980s, through years of jokes, the performance of AC arresters in various professional arrester plants is not far behind the most advanced products in the United States, Japan, Western Europe and other countries. Products that truly meet all the requirements of the national standard can also meet all the requirements of the international IEC standard.

Porcelain coated silicon carbide valve arrester is a full series of independent technology arrester developed and produced by lightning arrester researchers in New China. This product fully combines the actual situation of China's power grid at that time. The working performance of the porcelain blowing gap series products is still no less than that of the metal oxide surge arresters advocated by Western countries such as the United States and Japan. It is a proud scientific and technological achievement in the independent industrialization of New China.

Conditions of Use

The normal use conditions of conventional products are as follows:

1. Ambient temperature: no higher than+40 ℃, no lower than - 40 ℃

2. Altitude: no more than 2000m;

3. Power frequency: 50 ± 2Hz 60 ± 2Hz;

4. Seismic intensity: 7 degree and below

5. Maximum wind speed: 35m/s;

6. For gapless oxidation products, the power frequency voltage applied for a long time shall not exceed the continuous operation voltage of the arrester;

7. For oxidation products with gaps, the short-time power frequency voltage rise at the installation point shall not exceed the rated voltage of the arrester;

8. For porcelain blow valve silicon carbide products, the short-time power frequency rise at the installation point shall not exceed the arc extinguishing voltage of the arrester.

The arrester shall be specially made for long-term use under the following abnormal conditions, and shall be specified when ordering:

1. The temperature or altitude exceeds the standard (plateau, tropical zone, cold zone, fully enclosed cabinet, close to electric furnace, etc.);

2. The use environment has serious moisture or other corrosive impurities (water, salt fields, chemical plants, etc.);

3. Strong ultraviolet radiation (plateau, drought area with strong sunshine, etc.);

4. Particularly polluted areas (mine working face, construction site working face, etc.).