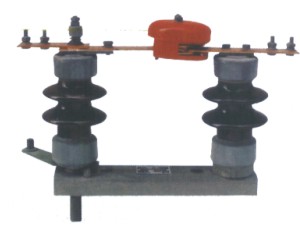

GW4 Old Type (Copper Bar Contact Arm) Uutdoor AC High-voltage Disconnector

High voltage disconnectors are important switching devices in the electrical system of power plants and substations, which need to be used together with high-voltage circuit breakers. The disconnector is applicable to indoor devices with three-phase AC 50Hz and rated voltage of 12KV. It is used to connect, cut off or transfer lines under the condition of voltage and load of high-voltage equipment. Its main functions are: to ensure the safety of high-voltage electrical appliances and devices during maintenance, and to isolate the voltage. It cannot be used to cut off and input load current and short-circuit current, but can only be used for some switching operations that do not produce strong arcs, that is, it does not have arc extinguishing function; It can be divided into indoor type and outdoor type according to different installation locations. It can be divided into single column type, double column type and three column type according to the number of insulating poles. Optional equipment is available for each voltage level.

GW4 type outdoor high-voltage disconnector is used for three-phase AC 50Hz outdoor high-voltage electrical equipment, which is used for opening and closing of lines under the condition of voltage and no load, and for electrical isolation of electrical equipment such as overhauled high-voltage buses and circuit breakers from live high-voltage lines. It can also be used for opening and closing small capacitive or inductive currents. When the knife switch is in the normal opening position, an insulation distance meeting the safety requirements can be provided. It is widely used in 35-220kV substations.

| 型号 | 额定电压 KV | 额定电流 A | 隔离开关 | |

| 额定峰值耐受电流KA | 45额定短时耐受电流KA | |||

| GW4一般型(防污型) | l2 | 630 | 50 | 20 |

| 1000 | 65 | 25 | ||

| 1250 | 80 | 31.5 | ||

| 17.5 | 630 | 50 | 20 | |

| 1000 | 65 | 25 | ||

| 1250 | 80 | 31 .5 | ||

| 40.5 | 630 | 50 | 20 | |

| 1000 | 65 | 25 | ||

| 1250 | 80 | 31.5 | ||

Conductive part

The fixed contact is composed of a copper plate bent into a right angle, and the perforated end of the fixed contact can be connected with the bus through a screw; The other end is short, and it contacts the moving blade (moving contact) when closing.

Two copper plates form a contact strip, also known as a moving contact, which can rotate around the shaft for a certain angle. When closing, it holds the static contact. There is a clamping spring between the two copper plates to adjust the contact pressure between the dynamic and static contacts. At the same time, when the two copper plates flow the current in the same direction, they generate mutually attractive electromotive force, which increases the contact pressure and improves the operation reliability. Galvanized steel sheet, called magnetic lock, is installed at both ends of the contact bar, which ensures the mutual attraction force generated by magnetic lock magnetization when passing the short-circuit fault current, strengthens the contact pressure of the contact, thus improving the dynamic and thermal stability of the disconnector.

Insulating part

The dynamic and static contacts are respectively fixed on two sets of supporting porcelain bottles. For the model with C, the moving contact is fixed on the bushing insulator. In order to insulate the moving contact from the metal and grounding transmission parts, porcelain insulated rod insulators are used.